Isiphi isizathu esiyinhloko sokugqoka amathuluzi okusika i-carbide enosimende

Thu Oct 20 16:35:20 CST 2022

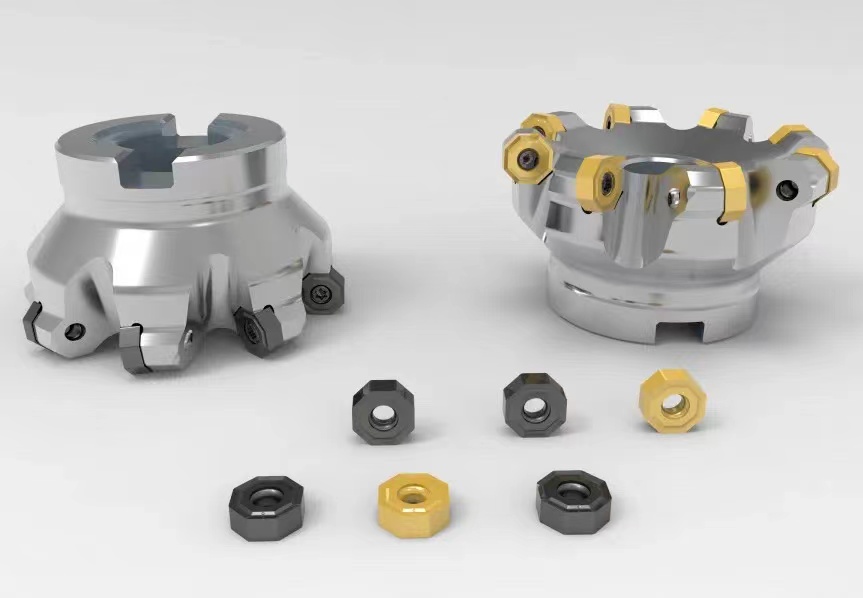

Abasiki be-carbide abakhiwe basetshenziswa kakhulu ngenxa yokubekezelelana komumo wabo omncane. Njengoba okufakiwe kungenakushintshwa ngokuqondile, abasiki abaningi bokugaya bayachithwa ngemva kokuwa kokufakwayo, okwandisa kakhulu izindleko zokucubungula. Manje sizohlaziya izizathu zokugqokwa kwe-carbide cutting tools.

1. Izici zezinto ezicutshunguliwe

Lapho usikwa ama-alloys e-titanium, ngenxa yokungaphatheki kahle okushisayo kwe-titanium alloys, ama-chips athambekele ekubeni nebhondi noma enze imiphetho ye-swarf eduze komphetho wephuzu lethuluzi, akhe izindawo ezinokushisa okuphezulu ngaphambili nangemuva. izinhlangothi zobuso bokufaka eduze kwethiphu yethuluzi, okubangela ukuthi ithuluzi lilahlekelwe ububomvu nobulukhuni futhi likhule ukuguga. Ekusikeni okuqhubekayo kwezinga lokushisa eliphezulu, ukunamathela nokuhlanganisa kuzothinteka ngokucubungula okulandelayo. Enqubweni yokukhuhla ngempoqo, ingxenye yezinto zamathuluzi izothathwa, okubangela ukukhubazeka kwamathuluzi nokulimala. Ukwengeza, lapho izinga lokushisa lokusika lifinyelela ku-600 ° C noma ngaphezulu, kuzokwakheka ungqimba oluqinile oluqinile phezu kwengxenye, enomthelela onamandla wokuhuzuka ku-ithuluzi lokusika. Ingxubevange ye-Titanium ine-modulus ephansi yokunwebeka kanye ne-elastic deformation enkulu. Ingaphezulu lendawo yokusebenza eduze nendawo engasehlangothini liphindela emuva kakhulu, ngakho indawo yokuxhumana phakathi kwendawo ecutshunguliwe kanye nendawo yeflank inkulu, futhi ukugqokwa kubucayi.

2. ukugqoka okujwayelekile

Ekucutshungulweni okuvamile, lapho umkhawulo wokugaya okuqhubekayo wezingxenye zengxube ye-titanium ifinyelela ku-15mm-20mm, ukuguga okuqinile kuzokwenzeka. Ukusebenza kahle kokugaya okuqhubekayo kuphansi kakhulu, futhi ukuphela kwendawo yokusebenza kubi kakhulu, okungakwazi ukuhlangabezana nezidingo zokukhiqiza nekhwalithi.

3. Ukusebenza okungalungile

Ngesikhathi sokucutshungulwa kokusakazwa kwe-titanium alloy okufana namakhava amabhokisi, ukusebenza okungalungile njengokugoqa okungafanele, ukujula kokusika okungafanele, isivinini sokupholisa ngokweqile, ukupholisa okunganele, njll., kuzobangela ukuthi ithuluzi liwe, lonakale, noma liphuke. Ngaphezu kokungasebenzi kahle kwalolu hlobo lokugaya i-milling cutter, kuzophinde kubangele ukukhubazeka okufana nokuma kwe-concave yendawo emshinini ngenxa "yokulunywa" ngesikhathi sokugaya, okungathinti kuphela ikhwalithi yendawo yokugaya, kodwa futhi kuholela ekumoshweni kwe-workpiece ezimeni ezibucayi.

4. Ukugqoka kwamakhemikhali

Ngaphansi kwezinga lokushisa elithile, into engu- ithuluzi lokusika nokunye kwemidiya ezungezile kunokusebenzelana kwamakhemikhali, okwenza ungqimba lwenhlanganisela yokuqina okuphansi phezu kwethuluzi, futhi ama-chips noma ucezu lokusebenza luyasulwa ukuze kwakheka imihuzuko. nokugqokwa kwamakhemikhali.

5. isigaba siyaguga

Lapho izinga lokushisa lokusika lifinyelela noma lidlula izinga lokushisa lesigaba lempahla yethuluzi lokusika, i-microstructure yezinto zamathuluzi izoshintsha, futhi ubulukhuni buzokwehla kakhulu, futhi okuwumphumela ithuluzi lokusika ukugqoka kubizwa ngokuthi ukuguqulwa kwesigaba. gqoka.